Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

Why Use Chains When Lifting: The Complete Advantage Guide

Introduction

Choosing the wrong lifting sling type can cost your company thousands in premature replacement, downtime, or safety incidents. Yet many operations still rely on synthetic slings or wire rope in situations where lifting chains would deliver superior performance and long-term value. This guide explains why lifting chains have become the industry standard for demanding applications, and how they compare to alternatives across durability, cost, and safety.

Whether you're managing a steel fabrication shop, shipbuilding facility, or heavy construction site, understanding the advantages of lifting chains helps you make decisions that protect your workers and your bottom line. We'll examine the real-world benefits that make chains the preferred choice for professionals who can't afford equipment failure.

The Core Advantages of Lifting Chains

Lifting chains offer a combination of benefits that no other sling material can match. These advantages stem from the fundamental design and material properties of alloy steel chain, which has been refined over more than a century of industrial use.

Superior Durability in Harsh Environments

Durability is where lifting chains truly excel. Unlike synthetic slings, which degrade under UV exposure and heat, or wire rope, which can corrode and kink, lifting chains resist the punishment of real-world industrial work.

Temperature Resistance is one of the most significant advantages. Alloy steel chains can operate safely from -40°F to 400°F without any reduction in working load limit. Compare this to synthetic slings, which have a maximum temperature limit of just 194°F. In steel mills, foundries, and other high-heat environments, this temperature range makes chains the only viable option. If you're working above 400°F, chains can still be used with manufacturer-approved load reductions, giving you flexibility that other sling materials simply don't provide.

Chemical and Environmental Resistance is equally important. Lifting chains resist oils, solvents, and chemicals that would damage synthetic fibers. They're unaffected by UV radiation, so they can be stored outdoors without degradation. In dirty or contaminated environments—common in manufacturing and construction—chains maintain their integrity while synthetic slings deteriorate.

Abrasion and Impact Resistance means chains can handle rough loads with sharp edges or irregular surfaces. Wire rope can be crushed or kinked by a single impact; chains distribute the load across multiple links and continue functioning. This resilience translates directly into longer service life and fewer emergency replacements.

Exceptional Versatility and Adjustability

Unlike synthetic or wire rope slings, lifting chains can be adjusted in the field to match your specific lifting requirements. This flexibility is a major advantage that many operations overlook.

Field Adjustability allows you to shorten individual legs using grab hooks or shorteners, accommodating uneven loads or unusual load geometries without ordering new equipment. If your load configuration changes, you adapt your chain sling rather than purchasing a new one. This capability is impossible with synthetic slings, which are manufactured to fixed lengths and cannot be adjusted. Wire rope slings also lack this flexibility, forcing you to maintain multiple slings for different applications.

Field Construction means you can assemble chain slings on-site using standard components. If you need a specific configuration or length, your rigging crew can build it from available chain and hardware. This reduces inventory requirements and gives you immediate solutions to lifting challenges.

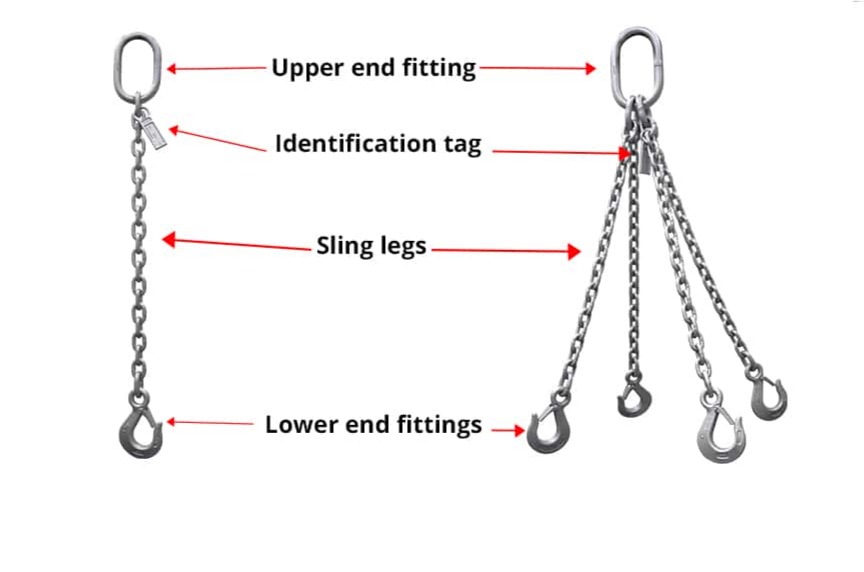

Multiple Configurations are possible with the same chain stock. A single length of chain can be configured as a single-leg sling, double-leg sling, triple-leg sling, or quad-leg sling depending on your load and lifting points. This versatility means you need fewer different slings in inventory, reducing capital investment and storage space.

Easy Inspection and Complete Repairability

Inspection and maintenance are critical for lifting safety, and chains have significant advantages here as well.

Visual Inspection of chains is straightforward. You can see the condition of every link, identify wear or damage immediately, and make informed decisions about when to retire a sling. The ASTM standard requires that alloy chain slings elongate at least 20% when overloaded, providing a visible warning sign that the sling has been overstressed and must be removed from service. This safety feature is built into the material itself—no additional monitoring required.

Complete Repairability is a major cost advantage. If a chain link is damaged, it can be replaced or the chain can be shortened by removing damaged sections. If a hook is damaged, it can be replaced without replacing the entire sling. Compare this to synthetic slings, where any damage to the load-bearing fibers requires destroying and disposing of the entire sling. Wire rope slings have similar limitations—once damaged, they must be scrapped.

Easy Maintenance means your chains stay in service longer. Regular inspection, cleaning, and lubrication keep chains performing optimally. Unlike synthetic slings that can't be maintained, or wire rope that requires specialized care, chain maintenance is simple and inexpensive.

Lifting Chains vs. Synthetic Slings: A Detailed Comparison

Synthetic slings (web slings and roundslings) are popular because of their low initial cost and light weight. However, this cost advantage disappears quickly when you factor in durability and service life.

Durability Comparison

The durability difference is stark. Synthetic slings are damaged by UV radiation, chemicals, oils, and heat. A synthetic sling stored outdoors in sunlight will degrade significantly within months. The same sling exposed to oils or solvents will lose strength. In environments above 194°F, synthetic slings cannot be used at all.

Lifting chains, by contrast, thrive in these environments. A chain sling stored outdoors for years remains fully functional. Exposure to oils, solvents, and chemicals doesn't affect performance. Temperature extremes from -40°F to 400°F don't reduce working load limit. This environmental resistance means chains maintain their value and safety over years of service.

Cost-Benefit Analysis

While synthetic slings cost less initially—often 30-50% less than comparable chain slings—the total cost of ownership strongly favors chains. A synthetic sling might cost $200, but it needs replacement every 2-3 years in typical industrial use. Over a 10-year period, you'll purchase 3-5 synthetic slings, spending $600-$1,000 total.

A chain sling might cost $400 initially, but it will last 10+ years with proper maintenance. The chain may require occasional link replacement or hook repair, costing $50-$100 total over its lifetime. Your total 10-year cost is $450-$500—less than half the synthetic sling cost.

Adjustability and Versatility

Synthetic slings are manufactured to fixed lengths and cannot be adjusted. If you need a different length, you must purchase a new sling. If you need to shorten a leg to balance an uneven load, you cannot do it with a synthetic sling.

Lifting chains solve this problem. You can adjust length by using grab hooks to shorten individual legs. You can reconfigure from a 2-leg to a 4-leg sling by adding additional legs. This versatility means you need fewer different slings in inventory, reducing capital investment and storage requirements.

Inspection and Repair

Synthetic slings cannot be repaired. Once damaged, they must be destroyed and disposed of. This creates waste and expense every time a sling is damaged.

Lifting chains can be repaired. A damaged link can be replaced. A worn hook can be replaced. The chain itself can be shortened by removing damaged sections. This repairability extends service life and reduces long-term costs.

Lifting Chains vs. Wire Rope Slings: Understanding the Tradeoffs

Wire rope slings are popular in some applications because they offer high strength in a smaller diameter and lower initial cost than chains. However, they have significant limitations that make chains the better choice for many operations.

Strength and Flexibility

Wire rope slings offer excellent strength-to-weight ratio and flexibility, making them ideal for applications where the sling must bend around loads or fit into tight spaces. However, this flexibility comes with a cost: wire rope is susceptible to kinking, crushing, and abrasion damage.

A single kink or crush in wire rope can reduce strength by 50% or more. Once kinked, the damage is permanent and the sling must be scrapped. Lifting chains, by contrast, can handle impacts and rough handling without permanent damage. A chain that's been crushed or bent can often be straightened or repaired.

Inspection Challenges

Wire rope is difficult to inspect thoroughly. Damage can occur inside the rope core, where it's invisible to visual inspection. Internal corrosion can weaken the rope without any external signs. This hidden damage creates safety risks—a rope that appears sound might fail suddenly under load.

Lifting chains are easy to inspect. Every link is visible and accessible. Damage is immediately apparent. The 20% elongation standard provides a built-in warning system—if a chain has been overstressed, the elongation is visible and the sling is immediately removed from service.

Repairability and Cost

Wire rope slings cannot be repaired. Once damaged, the entire sling must be destroyed and disposed of. If the hardware (master links and hooks) is undamaged, it can be reused with new rope, but the rope itself is lost.

Lifting chains can be repaired. Damaged links can be replaced. Hooks can be replaced. The chain can be shortened by removing damaged sections. This repairability significantly extends service life and reduces replacement costs.

Temperature Limitations

Wire rope slings have temperature limitations similar to synthetic slings. Steel core wire rope should not be used above 400°F or below -40°F. Fiber core wire rope has even lower temperature limits.

Lifting chains can operate from -40°F to 400°F without load limit reduction, and can be used above 400°F with manufacturer approval. This temperature range makes chains the only choice for high-heat applications.

Safety and Compliance: Why Standards Recommend Chains

Industry standards—ASME (American Society of Mechanical Engineers), NACM (National Association of Chain Manufacturers), and OSHA (Occupational Safety and Health Administration)—recommend alloy steel chains for overhead lifting. This isn't arbitrary; it's based on decades of safety data and real-world performance.

ASME and OSHA Standards

The standards specify that only Grade 80, Grade 100, and Grade 120 alloy steel chains are acceptable for overhead lifting. Grades below 80 are designated for transport use only, not lifting. This distinction reflects the superior strength and reliability of alloy chains.

The standards require that chain slings be marked with grade, size, and working load limit. This marking system ensures that riggers can quickly verify that a sling is appropriate for the intended load. Unmarked chains should never be used for lifting.

Built-In Safety Features

Alloy steel chains have a built-in safety feature that other sling materials lack. Per ASTM standards, alloy chains must elongate at least 20% when overloaded. This elongation is visible—a rigger can immediately see that the chain has been overstressed and remove it from service before failure occurs.

Synthetic slings and wire rope have no such indicator. They can fail suddenly without warning, creating catastrophic safety risks. The 20% elongation standard is a critical safety advantage that makes chains the preferred choice for safety-conscious operations.

Load Rating and Design Factors

Chain slings operate with a 4:1 design factor, meaning the breaking strength is four times the rated working load limit. This conservative design factor provides a safety margin that accounts for wear, corrosion, and variations in loading that aren't readily apparent.

Wire rope slings use a 5:1 design factor, which might seem more conservative. However, this higher factor is necessary because wire rope is more susceptible to hidden damage and corrosion. The 4:1 factor for chains reflects the superior durability and reliability of alloy steel.

Real-World Applications: Where Chains Excel

Understanding where lifting chains provide the greatest advantage helps you make informed decisions about sling selection.

Steel Fabrication and Metalworking

Steel fabrication shops handle hot materials, sharp edges, and heavy loads—conditions that quickly destroy synthetic slings and damage wire rope. Lifting chains thrive in these environments. The high temperature resistance allows chains to lift hot steel directly from furnaces. The abrasion resistance handles rough, sharp-edged loads. The durability means chains last for years in these demanding conditions.

Shipbuilding and Heavy Construction

Shipbuilding and heavy construction involve massive loads, awkward geometries, and rough handling. Chains' adjustability allows riggers to configure slings for unusual load shapes. The durability handles the rough treatment common in these industries. The repairability means damaged slings can be fixed rather than replaced, reducing downtime and cost.

High-Temperature Environments

Foundries, forges, and other high-temperature facilities operate well above the temperature limits of synthetic slings and wire rope. Lifting chains are the only sling option that can safely handle these environments. The ability to lift hot materials directly, without waiting for cooling, improves efficiency and reduces production time.

Outdoor and Contaminated Environments

Construction sites, mining operations, and outdoor manufacturing expose slings to UV radiation, weather, chemicals, and dirt. Synthetic slings degrade quickly in these conditions. Lifting chains remain fully functional regardless of environmental exposure. This durability makes chains the cost-effective choice for outdoor and contaminated environments.

Cost-Benefit Analysis: The Long-Term Value Proposition

While lifting chains cost more initially than synthetic slings or wire rope, the total cost of ownership strongly favors chains when you factor in durability, repairability, and service life.

Initial Cost vs. Service Life

A typical synthetic sling costs $150-$300 and lasts 2-3 years in industrial use. A comparable lifting chain costs $300-$500 and lasts 10+ years. Over a 10-year period, the synthetic sling requires 3-5 replacements, totaling $450-$1,500. The chain requires minimal maintenance and perhaps one hook replacement, totaling $50-$100.

The chain's 10-year cost is $350-$600. The synthetic sling's 10-year cost is $450-$1,500. The chain saves money over time despite higher initial cost.

Maintenance and Repair Costs

Synthetic slings require no maintenance but cannot be repaired. When damaged, they're discarded and replaced.

Wire rope slings require periodic inspection and lubrication. When damaged, they cannot be repaired and must be replaced.

Lifting chains require periodic inspection and occasional lubrication. When damaged, they can often be repaired by replacing a link or hook, extending service life at minimal cost.

Downtime and Productivity

When a synthetic sling fails, you must stop work, obtain a replacement, and resume operations. This downtime costs far more than the sling itself. Lifting chains' superior durability means fewer failures and less downtime. When a chain does require repair, it can often be fixed on-site rather than replaced, minimizing downtime.

Safety and Liability

Using the wrong sling type for an application creates safety risks and potential liability. If an accident occurs and investigation reveals that an inappropriate sling was used, liability exposure is significant. Using lifting chains—the industry-standard choice—demonstrates that you're following best practices and industry standards. This reduces liability risk and shows due diligence in safety management.

Practical Guidance: Choosing Chains for Your Application

Understanding when to use lifting chains helps you make the best decision for your specific needs.

Use Lifting Chains When

You're lifting in high-temperature environments (above 194°F), you're handling rough or sharp-edged loads, you need adjustable sling length, you require long service life and low total cost of ownership, you're working in outdoor or contaminated environments, you need slings that can be repaired and maintained, or you're subject to OSHA or ASME compliance requirements.

Consider Alternatives When

You need maximum flexibility around irregular loads (wire rope might be better), you have very tight space constraints and need minimal sling diameter (wire rope might be better), or you have a one-time lifting task with minimal budget (synthetic might be acceptable, though not recommended).

In most industrial applications, lifting chains are the superior choice. The advantages in durability, safety, repairability, and long-term cost make chains the preferred option for professionals who understand the true cost of equipment failure.

Conclusion

Lifting chains represent the industry standard for overhead lifting because they deliver superior performance across every important dimension: durability, safety, versatility, and long-term cost. While synthetic slings and wire rope have their place in specific applications, lifting chains are the choice for demanding industrial work where reliability and safety are paramount.

The advantages are clear: chains resist extreme temperatures, chemicals, and abrasion; they can be adjusted and repaired; they're easy to inspect; and they provide decades of service life. Over the long term, chains cost less than alternatives when you account for replacement frequency, maintenance, and downtime.

If you're currently using synthetic slings or wire rope in demanding applications, switching to lifting chains could reduce costs, improve safety, and increase uptime. Ready to make the switch? Our lifting specialists at lifting-chain.com can help you select the right chain configuration for your specific application. We'll evaluate your lifting requirements, recommend the appropriate grade and size, and ensure you have the right sling for safe, efficient operation. Contact us today for a free consultation—let's find the perfect lifting chain solution for your operation.