Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

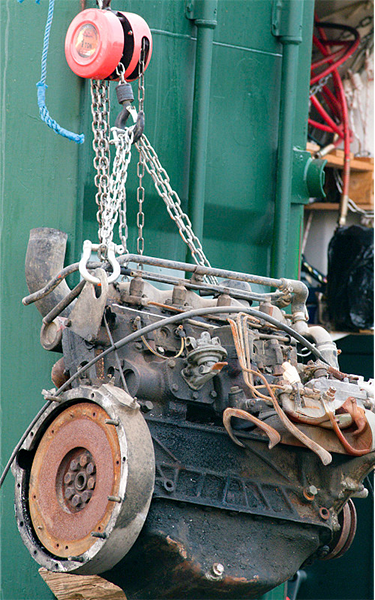

Lifting an engine is a high-risk task if done incorrectly. Whether you are working in an automotive workshop, factory maintenance area, or construction site, using the right lifting chain and proper technique is critical to avoid injuries, equipment damage, or load failure.

This guide explains how to lift an engine with a chain safely, what type of lifting chain to use, common mistakes to avoid, and practical tips professionals rely on in real-world lifting operations.

A lifting chain is often preferred over straps or ropes when lifting engines because engines are heavy, rigid, and have uneven centers of gravity.

High strength for concentrated loads

Excellent resistance to heat, oil, and sharp edges

Minimal stretch for better load control

Long service life under repeated lifting

For engine lifting, stability and control matter more than flexibility—and that’s where a lifting chain excels.

Before lifting an engine, selecting the correct lifting chain is essential.

Working Load Limit (WLL) higher than engine weight

Certified alloy lifting chain (G80 or higher)

Correct chain diameter

Proper hook and connection points

Many engine lifting accidents happen not because the engine is too heavy, but because the lifting chain was undersized or uncertified.

Most engines have designated lifting eyes or brackets. Always use manufacturer-approved lifting points—never wrap a chain around fragile components.

Connect the lifting chain evenly to the engine’s lifting points. If using two points, ensure both sides are balanced to prevent rotation.

Uneven chain angles can cause side loading. The more vertical the chain legs, the safer the lift.

Lift the engine just a few centimeters off the ground. Check:

Balance

Chain tension

Hook seating

Any unexpected movement

Avoid sudden movements. A smooth lift reduces shock loads on the lifting chain and crane.

Avoid these frequent errors:

Using non-lifting or ungraded chains

Ignoring chain angle effects

Lifting from non-approved engine parts

Overloading the lifting chain

Standing under the suspended engine

Even a high-quality lifting chain becomes unsafe when misused.

Item | Lifting Chain | Lifting Strap |

Strength | Very high | Medium |

Heat resistance | Excellent | Poor |

Oil resistance | Excellent | Limited |

Load control | Precise | Elastic |

Suitability for engines | Best choice | Not recommended |

This is why professional mechanics and riggers prefer a lifting chain for engine handling.

Before lifting:

Inspect the lifting chain for wear or deformation

Confirm WLL markings

Ensure hooks are fully seated

After lifting:

Lower the engine slowly

Release tension gradually

Store the lifting chain properly

Regular inspection extends both safety and service life.

In many workshops, engine lifting issues are blamed on “bad luck” or “heavy loads.” In reality, the most common cause is dirty or worn lifting equipment, especially chains contaminated with oil, debris, or corrosion.

Cleaning and maintaining your lifting chain regularly can prevent most lifting problems before they happen.

(If you want to reduce risk further, many professionals choose certified alloy lifting chains that maintain consistent strength even after repeated engine lifts—especially in oily or high-temperature environments.)

While any chain may look similar, only certified lifting chains are designed for overhead lifting. Using uncertified chain is dangerous and often illegal in professional settings.

If you are lifting engines frequently, investing in a properly tested alloy lifting chain is one of the simplest ways to improve safety and efficiency—without changing your workflow.

Knowing how to lift an engine with a chain is not just about technique—it’s about using the right lifting chain, applying correct angles, and respecting load limits.

A properly selected lifting chain provides stability, control, and long-term reliability for engine lifting tasks in workshops and industrial environments. When safety matters, correct chain choice and correct method always come first.