Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

G100 lifting chains use SCM440 alloy steel with precise elemental ratios:

Comparison Analysis of Lifting Chain Grades Parameter G100 G80 Critical Note: G100 chains should be used with Grade 100 shackles to maintain load integrity. Load Capacity Engineering

Load Capacity Engineering

Technical Specifications for Purchase

2. Quality Control Parameters

Parameter | Tolerance | Tolerance | |

Link Length | ±1% of nominal |

| |

Hardness | HRC 40-45 |

|

Failure Type | Root Cause | Preventive Measure |

Stress corrosion cracking | Chloride exposure | Apply MIL-PRF-16173 grease |

Fatigue fracture | Overloading | Install load cells + IoT monitors |

Improper splice failure | Wrong shackle size | Use ASME B30.26-compliant connectors |

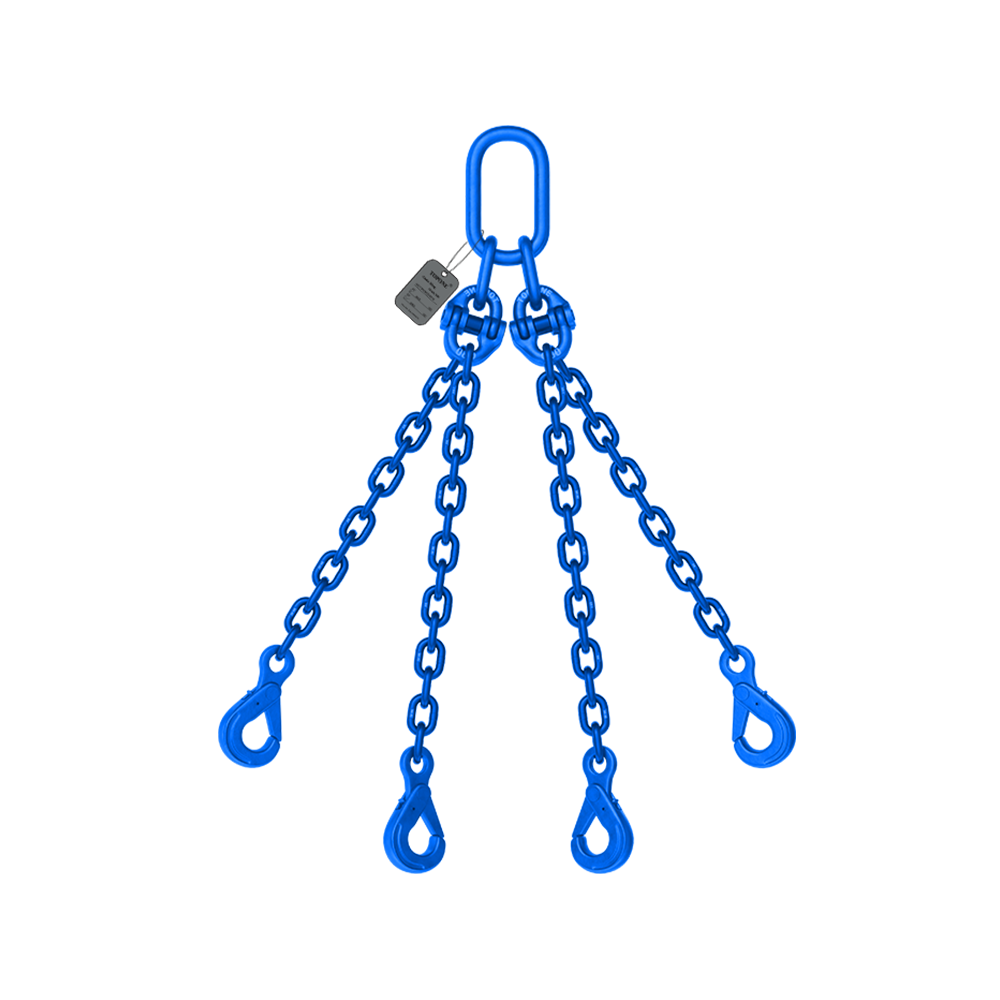

Xintai Taida Mirso Co., LTD delivers G80 alloy chains manufactured in our 15,000㎡ ISO 9001-certified facility, combining robotic welding precision (0.1mm accuracy) with ASME B30.9 compliance. With 9 automated lines producing 500,000+ chains annually, we serve 30+ countries across mining, maritime, and construction sectors.

Why Partner With Us?

✓ Certified Quality – EN 818-2 & DNVGL-OS-E304 certified

✓ Custom Solutions – Chains for extreme temps (-40°C to 400°C) and corrosive environments

✓ Global Support – 48-hour technical response & DDP shipping

Limited Offer: First orders over $3,000 receive free load calculation software.

Contact Our Engineers Today:

? [email protected]

? +86 18766656705

Serving global clients since 2008 with 98% on-time delivery rate.