Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

Sling Co (TOPONE®) runs nine automated lines that forge, weld, and proof-load more than 500 000 high-tensile ring chains every year, exporting to 30 U.S. and European markets. Six product families cover every certified need: Grade 100, Grade 80, Mining (DIN 22252), broad DIN pitch chains, NACM U.S. standards, and ASTM chemistry-controlled slings. Knowing which grade fits your lift saves headroom, rejects corrosion, and slashes downtime. The quick-swap matrix below bundles each family’s strength, environment, finish, and best hook choice so you decide once and lift safely for years.

Sling grade (link emboss) | Yield / Tensile (MPa) | WLL vs G80 | Ideal environment & duty | Hook & finish combo | Typical build & WLL* |

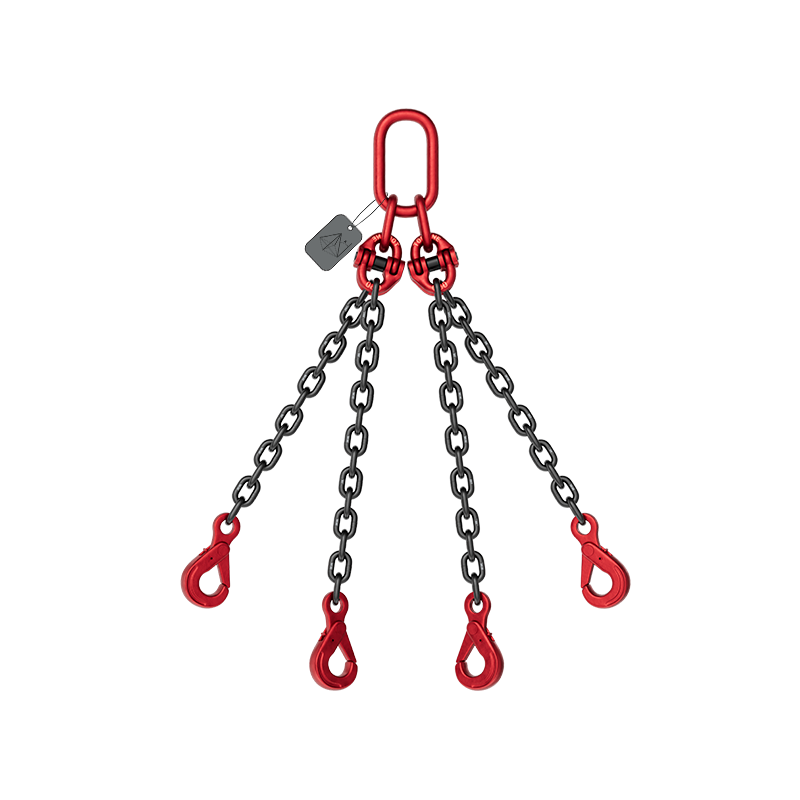

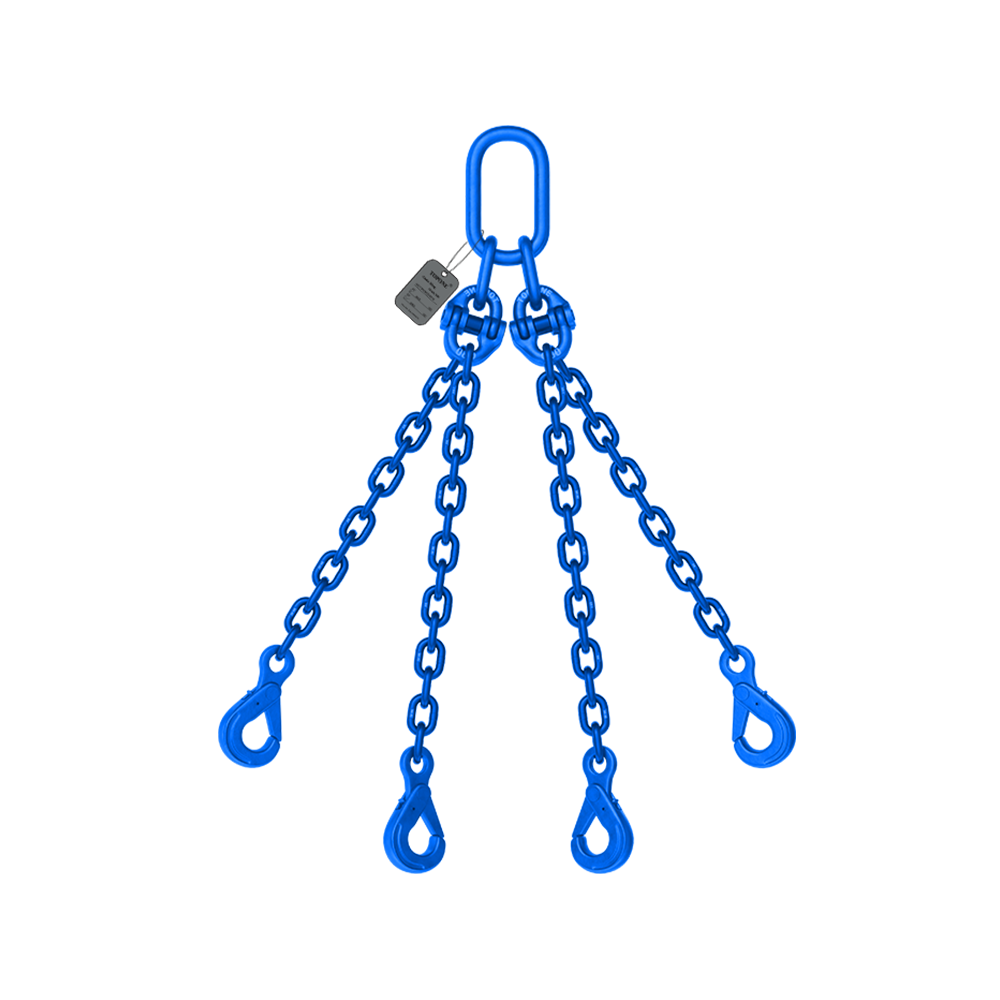

G100 “10TPN” | 980 / 1 180 | +25 % | Production lines, tight headroom | Selflocking + hotdip zinc | 4leg adjustable, Ø 10 mm → 4 t/leg |

G80 “8TPN” | 640 / 800 | Baseline | Construction, rental, fab shops | Clevis grab + Mnphosphate | 3leg sling, Ø 13 mm → 5.3 t/leg |

Mining Dgrade “DTPN” | ≥900 / >1 000 | +15 % skin hardness | Abrasive coal or salt mine | Spiral shackle + bare tempered | Doubleleg, Ø 18 mm → 10 t/leg |

DIN (764/766/763 etc.) | 640 / 800 (G80) | Baseline | Ship decks, farm drives | Calibrated link + hotdip zinc | 2leg, Ø 16 mm → 8 t/leg |

NACM (96/8490/2010) | 640 / 800 | Baseline | NorthAmerican cranes, OSHA audits | Eye sling + black paint | 20 ft lift hoist, Ø 10 mm → 3.15 t |

ASTM (A973/A391) | Grade specific | Same as spec | Petrochem, aerospace | Selflocking + epoxy | 1leg cert sling, Ø 13 mm → 5.3 t |

*Working-load limits follow EN 818-2 factors and Topone test sheets.

Grade first: decide if you need extra capacity (pick G100), extra hardness (pick Mining), salt/acid immunity (pick Stainless G80, not shown above), or a specific audit trail (pick DIN, NACM, or ASTM).

Diameter second: open the Topone diameter chart, find the first link whose single-leg WLL beats your load after you multiply by the sling-angle factor (1.4 at 45°, 2.1 at 60° for four legs).

Click to view:

Hooks and finish last: self-locking hooks autoclose overhead, clevis grabs shorten legs fast, foundry hooks open wide for ladles. Paint works indoors, phosphate beats dust, hot-dip zinc wins outdoors, polished stainless lasts forever in CIP wash-down lines.

Always gauge wear: scrap when mid-link diameter drops 10 % or five-link pitch grows 3 %.

Keep legs ≥45°: smaller angles double tension and kill WLL.

Oil after wash: even zinc loves a light film; stainless just needs a rinse.

Rack storage only: floors pool water; weld toes rust first.

These four habits push G80 service beyond four years, G100 to three, Mining chains to three in coal, and stainless beyond five in brine.

Finish | Saltspray life (h) | Added mass | Best grades | Lifecycle note |

Black paint | 72 | none | G63, G80 | Cheapest; respray yearly outdoors |

Mnphosphate | 480 | none | G80 | Handles dust; zero extra weight |

Hotdip zinc 70 µm | 1 000 | +3 % | G80, G100 | Fouryear rust delay on docks |

Polished stainless | Unlimited | none | Stainless G80 | No paint flakes; CIP ready |

Cost per tonne lifted often favours G100 in low headroom or high cycle yards and favours stainless when shutdowns cost more than hardware.

One table, four habits, and a finish choice are all you need to match any lift to the exact Sling Co chain sling grade—browse detailed sheets or request a quote at lifting-chain.com today.