Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

An alloy chain is one of the most critical components in industrial lifting, rigging, and hoisting systems. To ensure reliability and compliance, buyers must understand the technical specifications that define chain performance—such as grade, diameter, working load limit, and heat treatment quality.

This guide provides an in-depth look at alloy chain specifications, as well as a practical buying guide to help users choose the right alloy chain or alloy chain sling for heavy-duty operations.

Industrial alloy chains follow internationally recognized standards including EN 818, ISO, CE, NACM, and TÜV. Below are the core technical specifications that determine performance.

Standard lifting-grade alloy chain

High strength with strong resistance to wear

Suitable for most construction, mining, and manufacturing tasks

Approximately 25% higher WLL versus G80

Reduces total sling weight

Preferred in offshore, steel production, and heavy industrial lifting

High-grade alloy steel undergoes quenching + tempering to achieve superior tensile strength and fatigue resistance.

Chain diameter directly affects allowable load capacity.

Larger diameters → higher WLL → heavier lifting applications.

Example (typical values based on EN 818):

Diameter | G80 WLL (t) | G100 WLL (t) |

6 mm | 1.12 t | 1.40 t |

8 mm | 2.00 t | 2.50 t |

10 mm | 3.15 t | 4.00 t |

13 mm | 5.30 t | 6.70 t |

16 mm | 8.00 t | 10.00 t |

Understanding these values helps ensure compliance and correct sizing of alloy sling chain and multi-leg chain slings.

A high-performance alloy chain must undergo:

Quenching → increases hardness

Tempering → balances strength and ductility

Calibration → ensures uniform link dimensions

Proof load testing → verifies lifting capability

Heat treatment quality directly impacts fatigue resistance and lifespan.

Depending on application, alloy chains are available with:

Black lacquer finish

Powder coating

Hot-dip galvanizing

Special anti-corrosion coatings

Stainless alloy chain (marine grade)

Surface finish affects not only durability but also operational safety.

Every alloy chain must maintain precise link dimensions:

Inside width

Outside width

Pitch length

Weld seam integrity

Straightness and link alignment

Consistency ensures smooth assembly into alloy chain slings and compatibility with hooks, master links, and connectors.

Choosing the correct alloy chain is essential for safe, efficient lifting. This guide helps buyers avoid mismatched chain specifications and select the highest-performing product for their application.

Always choose an alloy chain with a WLL equal to or greater than the maximum anticipated lifting load.

Consider additional forces from:

Sling angle

Dynamic movement

Uneven load distribution

Higher WLL = safer lifting operation.

Use G80 for general industrial tasks.

Choose G100 for high-capacity, high-efficiency lifting.

For offshore or mining operations, G100 is typically preferred due to lighter weight and higher strength.

Examples:

8–10 mm → Medium-duty lifting

13–16 mm → Heavy-duty engineering & machinery lifting

18–22 mm → Extremely heavy industrial loads

Diameter affects both capacity and compatibility with hooks and master links.

Only purchase alloy chain that includes:

CE or TÜV certification

EN 818 compliance

Batch/heat number

Manufacturer identification

Test documentation

This ensures legal compliance and operational safety.

If used in harsh environments, choose:

Galvanized alloy chain → marine or outdoor settings

Stainless alloy chain → chemical plants or corrosion-prone areas

Heat-resistant alloy chain → steel mills, foundries

Matching chain type to environment extends service life significantly.

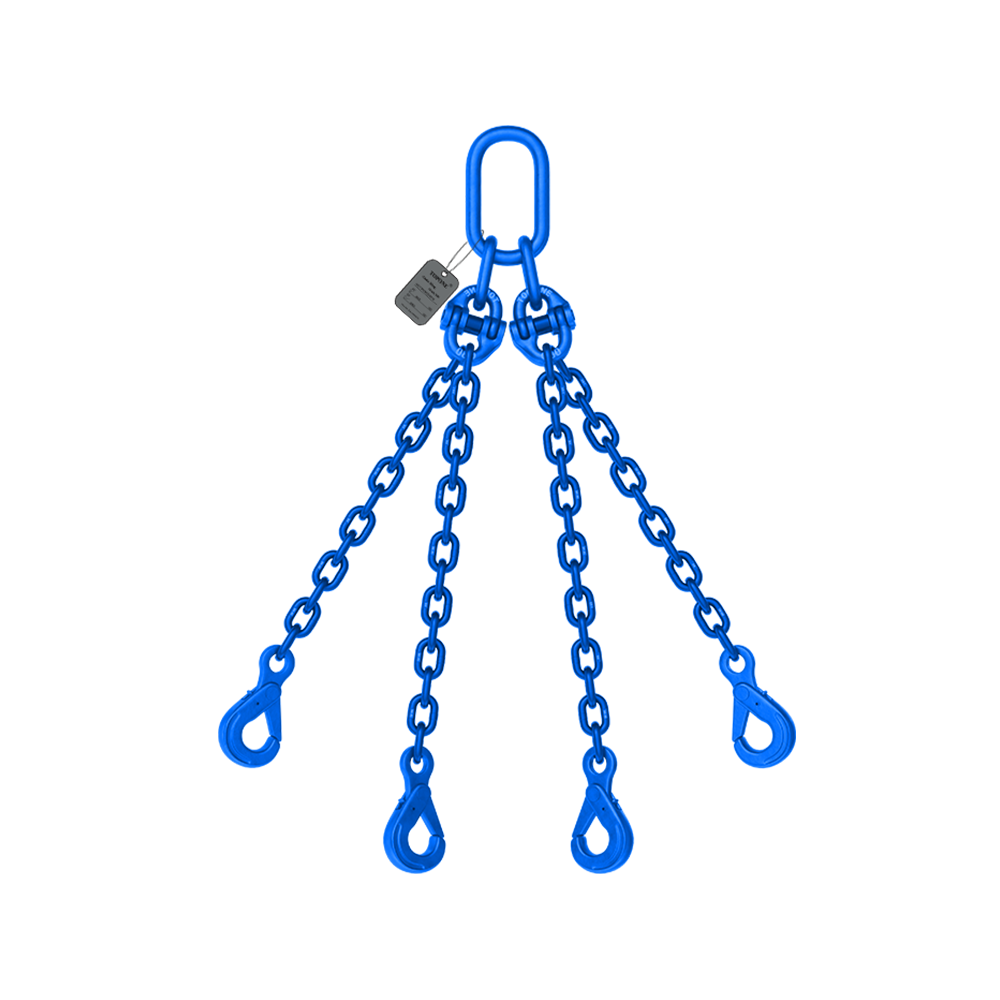

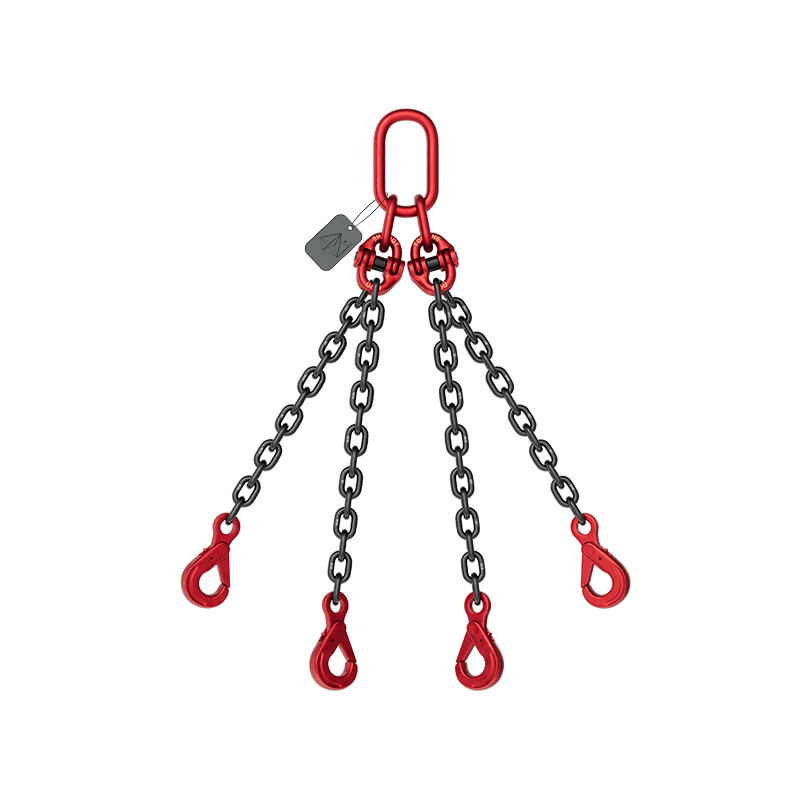

For multi-leg sling systems, ensure your alloy chain matches:

Hook type

Master link size

Shortening clutch compatibility

Sling angle requirements

Assembly specifications

A mismatched alloy chain can compromise the entire sling system.

A premium alloy chain ensures:

Longer service life

Higher fatigue resistance

Better lifting stability

Improved safety margins

Lower long-term operating cost

Since alloy chain is the load-bearing backbone of every chain sling, choosing the right chain directly affects overall lifting performance.

TOPONE CHAIN® produces industry-certified alloy chain for global heavy-lifting applications. Our advantages include:

G80 & G100 alloy chain manufacturing

Advanced heat-treatment and calibration lines

Precision dimensional control

Full traceability & CE/TÜV/ISO certification

OEM/ODM sling chain production

Compatibility with all alloy chain slings

Our alloy chain is the foundation of all TOPONE CHAIN® alloy sling and chain assemblies.

Understanding alloy chain technical specifications and selecting the right product is essential for safe heavy-lifting operations.

From material grade and WLL to diameter, treatment, and environmental suitability, each factor contributes to the performance of alloy chain slings, alloy sling and chain, and complete chain sling systems.

For globally certified alloy chains engineered for industrial lifting, TOPONE CHAIN® remains a trusted, high-quality manufacturer.