Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

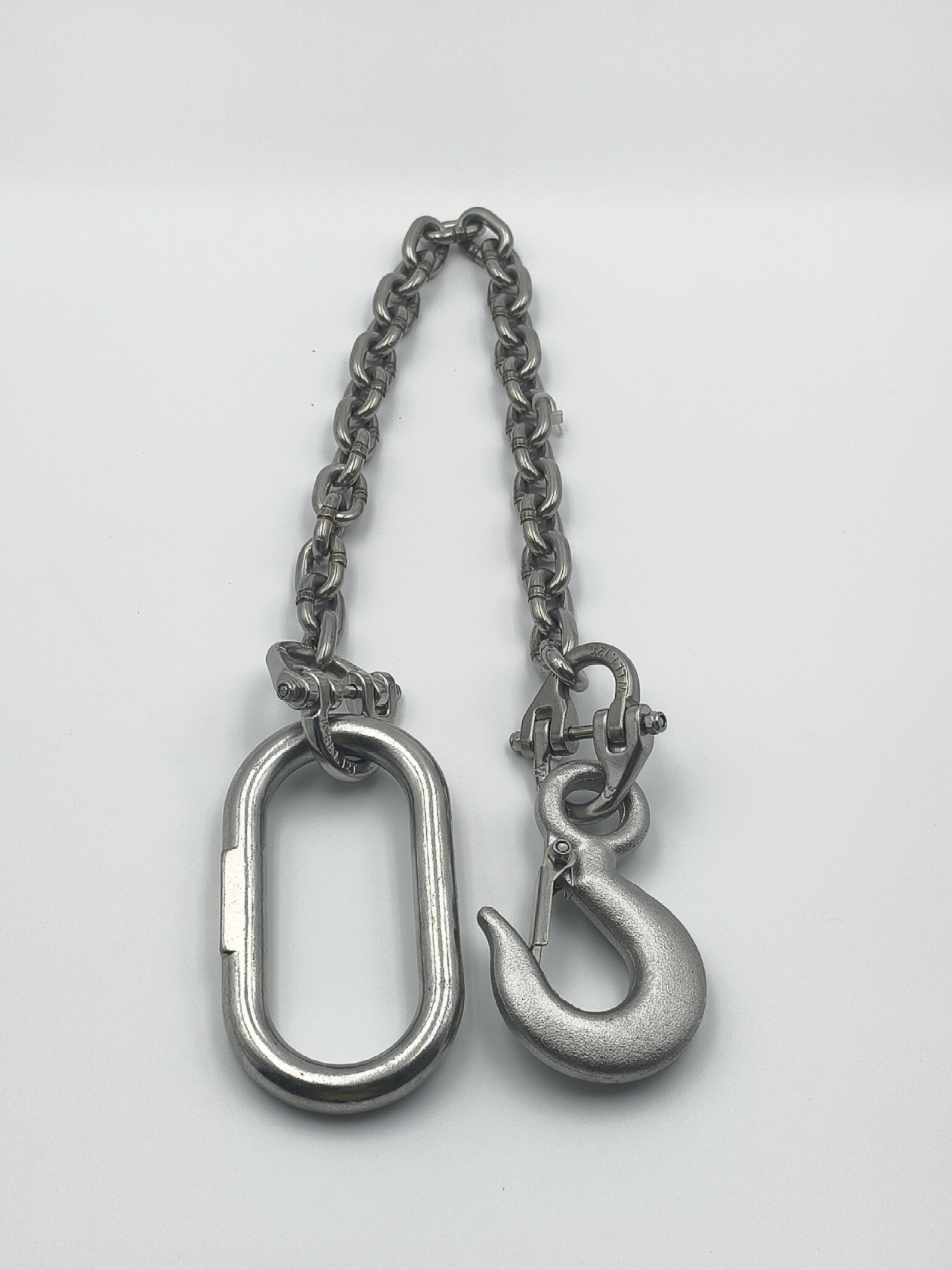

You face brine, detergents, and constant wash-down, yet you still need traceable capacity and predictable handling. A stainless G80 lifting chain solves that problem because it delivers grade-level strength without any coating and it cleans quickly for fast return to service. This guide explains how stainless G80 lifting chains reach the grade, where they excel, how you size and inspect them, and when you should pick another option. Use the checklists and the table to plan chain lifting in food and chemical plants, marine yards, and salt operations; then compare configurations alongside other chain slings for sale without guesswork.

Manufacturers achieve the grade through controlled melting, precise welding, and a quench-and-temper sequence tailored to stainless alloys. They finish the link surface by polishing and passivation to remove free iron and enhance corrosion resistance. You never add paint or plated coatings to a stainless G80 assembly, because coatings introduce flake risks, alter tolerances, and complicate inspection. You still read the WLL from the tag and you still match components by grade and by material so the assembly behaves as one system.

Food, slaughter, and hygienic lines: You rinse, sanitize, and return to work because the chain carries no coating that can chip. The bright surface also helps you spot soil or damage quickly.

Marine and brine exposure: Chloride-rich spray and salt fog attack carbon steel first, yet stainless slows red-rust formation and reduces unplanned downtime.

Salt mining and high humidity: You keep surfaces readable and reduce abrasive rust scale, so inspections go faster and records stay clean.

In all cases, you pick hooks, master links, and shortening devices that match grade and resist the same environment.

Start with the heaviest routine load, not a one-off peak. Sketch lift points and lock the angle to vertical between 15° and 60°. Multiply the load by the correct factor, then open the manufacturer’s WLL chart and select the first diameter that clears the result. Leave ~10% hook-throat clearance at the load point. If headroom runs tight, consider a stainless G100 alternative for the same WLL at a smaller diameter; if budgets drive the decision and the geometry fits, stay with stainless G80.

Angle Factors (apply before selecting size)

Single-leg vertical: ×1.0

Two-leg 0°–45°: ×1.4 | Two-leg 45°–60°: use table (capacity drops)

Three/Four-leg 0°–45°: ×2.1 | 45°–60°: ×1.5–1.6

Choker: ×0.8 (reduce 20%)

Follow the published temperature band for G80 service: −40 °C to +200 °C at full rating; 200–300 °C derate 10%; 300–400 °C derate 25%; operate outside this range only after you remove the sling from service and consult the manufacturer. Stainless slows corrosion, yet it does not ignore aggressive media. Review chemical safety data, confirm media compatibility, and rinse with cold water after exposure to acids, alkalis, or disinfectants. Dry the assembly completely to discourage crevice corrosion in tight interfaces.

You protect the chain when you keep like-for-like materials together. Mixed stainless-to-carbon interfaces can create galvanic couples, so you either select stainless hooks, master links, and fittings or you isolate dissimilar metals with approved hardware. Use self-locking hooks above walkways for extra security and use grab/shortening devices to equalize legs without knots or twists. Back-hook any idle leg to the master link so nothing snags while the crane travels.

Place corner pads wherever links touch edges. If you cannot improve the radius, apply simple, documented reductions: R ≥ 2d → no reduction, R ≈ d → ×0.7, sharp edge → ×0.5. Add spreaders when geometry forces wide angles, and lift a few centimeters first to confirm leg sharing before you climb.

Check before every shift and schedule thorough examinations by a competent person. Retire the sling when you see:

Wear: average link diameter reduced ≥ 10%.

Stretch: five-link pitch growth ≥ 3%.

Hook deformation: throat opening > 10% over nominal.

Cracks, pitting, or heat tint on any component.

Stiff articulation or any sign of binding after cleaning.

ID loss on tags or embossing.

Record date, measurements, actions, and remarks so audits move quickly and crews trust the gear.

Use this single view to align environment, reason for stainless G80, and special notes while you evaluate chain slings for sale.

Environment | Why Stainless G80 | Notes for Chain Lifting |

Food/CIP/SIP | No coating to flake; fast wash-down | Rinse, dry, and log after sanitizer cycles |

Marine/Brine | Slows red rust and preserves markings | Protect edges; confirm chloride exposure limits |

Salt Mining | Better visual inspections; less scale | Match stainless fittings or isolate dissimilar metals |

Chemical Wash-Down | Resists many cleaners | Verify media compatibility; dry to prevent crevice attack |

Skip stainless G80 when processes involve strong oxidizing acids, fluoride systems, or other media that defeat common stainless grades. Step away from any lift that exceeds the temperature band, and consult the manufacturer when the job demands exceptional impact, magnetic limits, or unusual welding requirements. You control risk best when you match grade, material, geometry, and environment at the planning table rather than after the crane booms up.

Choose stainless G80 when you demand clean surfaces, reliable capacity, and fast wash-down recovery—then contact TOPONE CHAIN for a traceable configuration and a confirmed delivery window.