Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

Rigging success hangs on two decisions—chain grade and hook style. Make them once, and every lift runs smooth, saving headroom, labour, and audit time. Rush them, and crews fight stretch, corrosion, and surprise shutdowns. This guide breaks down Topone’s rigging-chain catalogue, shows how each grade lines up with hook options, and hands you a six-step flow that locks in the perfect assembly. All numbers match the data sheets at lifting-chain.com, so you pick with confidence.

Chain Grade | Yield MPa | WLL Factor* | Proof Load | Best Field | Hook Match |

G80 | 640 | 4 : 1 | 2.5 × WLL | Rental yards, construction | Clevis grab, eye sling |

G100 | 980 | 4 : 1 | 2.5 × WLL | Production cranes, tight headroom | Self-locking, foundry |

Stainless G80 | 640 | 4 : 1 | 2.5 × WLL | Food, chemical, marine | Stainless latch |

*Design factor—Topone rates every chain at one quarter of its minimum break.

Choose grade first; hook jaws, latch force, and master-link size follow the chain strength.

Ø mm | G80 WLL kg | G100 WLL kg | Stainless G80 WLL kg | Chain kg / m | Typical Hook Throat mm |

8 | 2 000 | 2 500 | 2 000 | 1.4 | 13 |

10 | 3 150 | 4 000 | 3 150 | 2.2 | 17 |

13 | 5 300 | 6 700 | 5 300 | 3.8 | 22 |

16 | 8 000 | 10 000 | 8 000 | 5.7 | 28 |

20 | 12 500 | 16 000 | 12 500 | 9.0 | 34 |

Values taken from Topone catalogue; proof tested at 2.5 × WLL.

G100 lifts twenty-five percent more with the same diameter, often letting you drop one size, reclaiming headroom, and shaving sling mass. Stainless keeps the G80 rating but outlives painted alloy links three-to-one in brine or acid vapour.

Clevis grab hook – snags any chain link, shortens legs without tools; perfect for variable loads.

Eye sling hook – smooth throat spreads force and resists tip wear; best for single-leg vertical picks.

Self-locking hook – latch shuts under load, never forgets to close; ideal for overhead personnel zones.

Foundry hook – wide mouth scoops ladle trunnions, saves time in hot-metal plants.

Always match hook grade to chain grade. A G100 link can shear a G80 hook during shock loading.

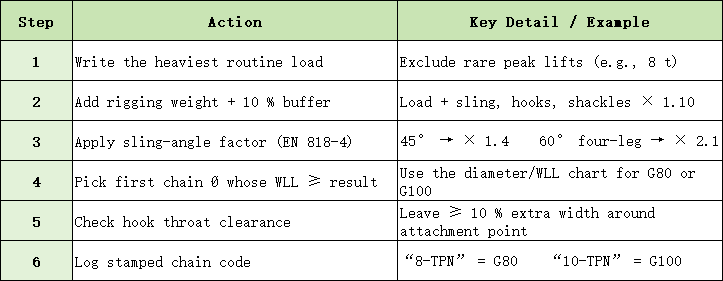

Write the heaviest routine load; ignore one-off peaks.

Add rigging weight plus ten percent buffer.

Multiply by sling-angle factor (1.4 @ 45°, 2.1 @ 60° four-leg) from EN 818-4.

Open the diameter table; pick the first link whose WLL beats the number.

Check hook throat against load point—leave ten-percent clearance.

Record stamped code (“8-TPN” for G80, “10-TPN” for G100) in the log before first lift.

Run these steps in a minute; you never oversize steel or undershoot strength.

Finish | Salt-Spray Life h | Temperature Range °C | Added Mass % | Field Choice |

Black lacquer | 72 | −40 → 200 | 0 | Indoor bays |

Mn-phosphate | 480 | −20 → 180 | 0 | Construction, mines |

Hot-dip zinc | 1 000 | −10 → 120 | 2-3 | Ports, decks |

Bare stainless | Unlimited | −196 → 200 | 0 | Clean rooms, acids |

Paint chips, zinc sacrifices, stainless endures—buy what the site justifies, not what looks shiny on day one.

Gauge mid-link diameter monthly—retire at ten-percent wear.

Measure five-link pitch—scrap at three-percent stretch; stretch shows overload faster than cracks.

Oil clean links lightly; oil blocks fretting and rust.

Replace hooks when tip gap grows five percent or latch fails one-hand snap test.

Hang slings on racks; floor moisture attacks weld toes first.

Good habits push G80 service past four years and G100 past three under daily use.

Assembly | Purchase USD | Life yrs | Tonnes Lifted / yr | Cost / t |

G80 Ø 16 + grab | 210 | 4 | 2 400 | 0.022 |

G100 Ø 13 + self-lock | 240 | 4 | 2 400 | 0.025 |

Stainless G80 Ø 16 + latch | 430 | 6 | 2 400 | 0.030 |

G100’s ticket edges up yet frees headroom and trims hook weight; stainless costs most but erases repaint downtime, winning total life in corrosive sites.

Follow the grade table, angle math, and finish checklist, then let Topone rigging chains carry the load while your crew carries less worry—order your perfect set now at lifting-chain.com.