Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

Searches for “lifting chains weightlifting” often mix gym training chains with industrial chain slings. Gym chains add resistance to barbell lifts; industrial chains carry real loads overhead under strict rules. This guide explains the difference clearly, then shows how to size and use industrial lifting chains for cranes and rigging. You will learn grade choices, working-load math, chain mass per metre, angle factors, edge protection, temperature limits, and inspection triggers—so every lift runs smoothly and audits stay simple. (98 words)

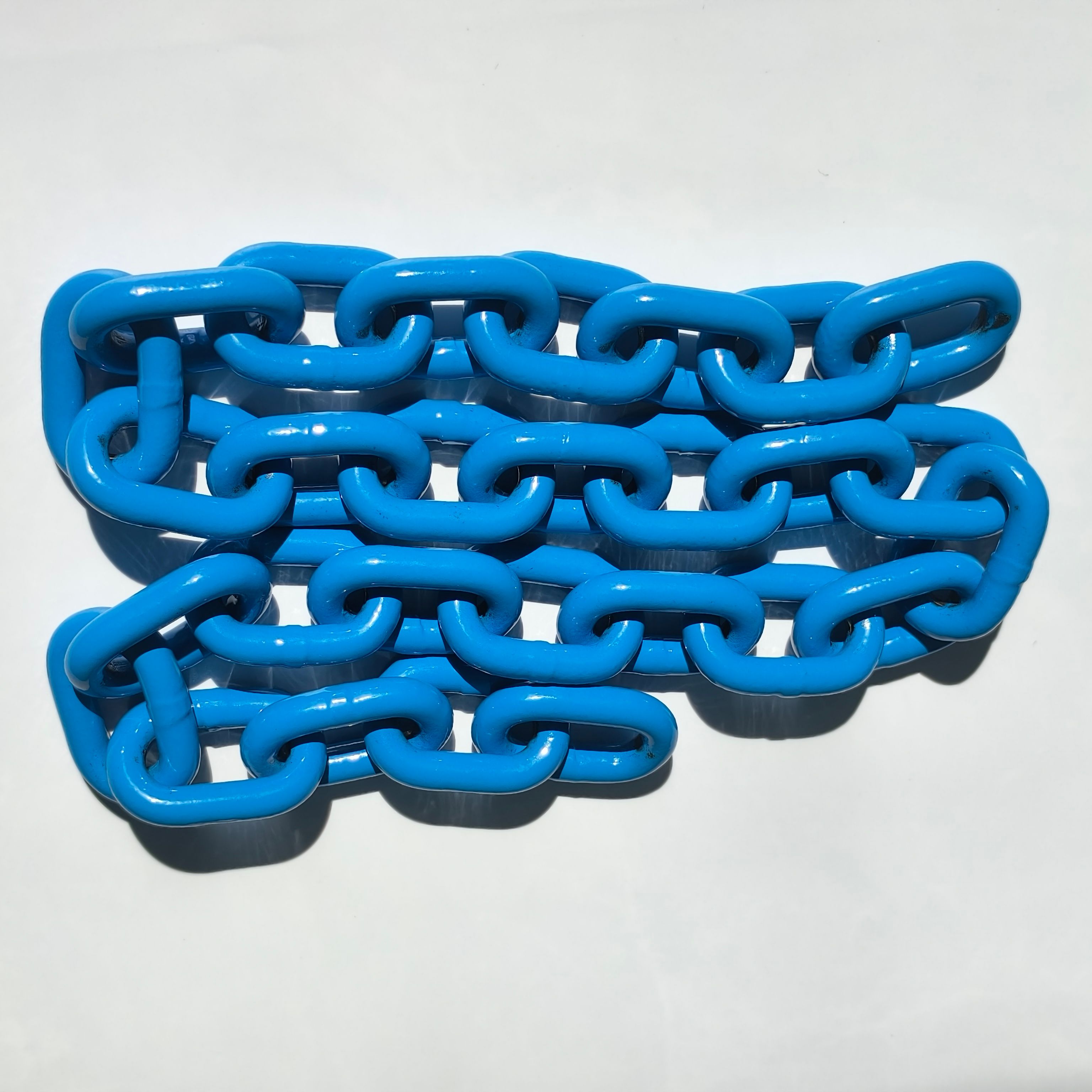

Gym weightlifting chains increase barbell resistance as links come off the floor. They do not carry rated Working Load Limits (WLL), they do not follow EN/NACM sling tables, and they do not suit overhead rigging. Industrial lifting chains—our products—use quenched-and-tempered alloy steel, grade-stamped components, and traceable proof tests. They lift engines, molds, beams, tanks, and prefabricated units; they never serve as gym accessories. Keep the terms straight and you keep people safe.

Choose Grade 80 (G80) when you want a proven workhorse for construction yards, rentals, and general fabrication.

Choose Grade 100 (G100) when headroom runs tight or you need higher WLL with the same diameter; G100 typically carries about 25% more WLL than the same-size G80, so crews often drop one diameter and recover hook travel.

Stainless G80 fits brine, food, or chemical wash-down lines and skips coatings entirely.

Rigging plans track two weights: the load and the rigging weight. The rigging weight matters because the crane lifts both. Use these typical mass-per-metre figures for common diameters on alloy round-link chain:

Chain Ø (mm) | Mass (kg/m) | Typical Single-Leg WLL (G80, kg) | Typical Single-Leg WLL (G100, kg) |

8 | 1.4 | 2,000 | 2,500 |

10 | 2.2 | 3,150 | 4,000 |

13 | 3.8 | 5,300 | 6,700 |

16 | 5.7 | 8,000 | 10,000 |

20 | 9.0 | 12,500 | 16,000 |

Use the exact table supplied with your chain sling; the values above match common published ranges for Topone chain.

Follow this quick flow before you order or rig:

<!--[if !supportLists]-->1. <!--[endif]-->Write the heaviest routine load. Ignore one-off peaks.

<!--[if !supportLists]-->2. <!--[endif]-->Add rigging weight—estimate chain legs from the table above, then add hooks, master links, and shackles.

<!--[if !supportLists]-->3. <!--[endif]-->Add 10% buffer for slings, shackles, and unknowns.

<!--[if !supportLists]-->4. <!--[endif]-->Multiply by the angle factor for multi-leg slings (see §5).

<!--[if !supportLists]-->5. <!--[endif]-->Open the WLL table for your grade and diameter; choose the first size that meets or beats the multiplied figure.

<!--[if !supportLists]-->6. <!--[endif]-->Check hook throat against the load point; leave ~10% clearance.

Worked example

<!--[if !supportLists]-->l <!--[endif]-->Load: 7,200 kg steel frame

<!--[if !supportLists]-->l <!--[endif]-->Rigging: Four G80 legs, Ø13 mm, ~3.8 kg/m × 4 legs × 3 m reach ≈ 45.6 kg; plus hardware ≈ 25 kg → 71 kg rigging

<!--[if !supportLists]-->l <!--[endif]-->Plan value: 7,200 + 71 = 7,271 kg; add 10% → 7,998 kg

<!--[if !supportLists]-->l <!--[endif]-->Angle: 4-leg at 60° → factor ~2.1/4 ≈ 0.525 per leg, or read directly from the manufacturer’s 4-leg table at 60°

<!--[if !supportLists]-->l <!--[endif]-->From the table: G80 Ø13 mm single-leg WLL 5,300 kg; 4-leg @ 60° published WLL typically ~18,000–23,000 kg (check your tag/table). This covers 7,998 kg comfortably; if headroom runs short, switch to G100 Ø13 or G80 Ø16 to create margin.

Grab/shortening hooks let you fine-tune leg length without knots or twists, so angles match and loads stay level. Eye sling hooks offer full-throat support for general picks; self-locking hooks snap shut under load and guard against tip-out where crews work underneath; foundry hooks deliver wide mouths for pins and trunnions. Always match hook grade to chain grade; never pair G80 hooks with G100 chain.

<!--[if !supportLists]-->l <!--[endif]-->Temperature: Operate from −40 °C to +200 °C at full rating; derate 10% from 200–300 °C and 25% from 300–400 °C; do not use beyond 400 °C or below −40 °C.

<!--[if !supportLists]-->l <!--[endif]-->Chemicals: Keep slings clear of acids, alkalis, and pickling solutions. If contamination happens, wash in cold water, dry, and send the sling to a competent person for inspection before reuse.

<!--[if !supportLists]-->l <!--[endif]-->Edges: Protect links at corners. If the edge radius R equals 2d (two times link diameter) or more, you typically avoid reduction; when R ≈ d, reduce capacity to ~70%; on sharp edges, reduce to ~50% or add proper corner pads or spreaders.

<!--[if !supportLists]-->l <!--[endif]-->Storage: Hang slings on racks, keep them dry and lightly oiled (stainless needs only rinse and dry), and tag out any damaged gear.

Inspect before use, then schedule thorough examinations at defined intervals. Withdraw the sling immediately if you see any of the following:

Trigger | What you look for |

Wear | Average link diameter reduced by 10% or more |

Stretch | Five-link pitch grown by 3% or more |

Hook deformation | Throat opening increased by >10% |

Cracks, heat tint, deep nicks | Any link or component |

Stiff articulation | Links fail to bend freely |

ID loss | Tag or embossing missing or unreadable |

Keep a simple inspection log—date, inspector, leg diameters, hook gap, remarks—and your slings pass audits without drama.

Q: Can I use gym “weightlifting chains” for overhead lifting?

A: No. Gym chains train athletes; they lack WLL, tags, grade stamps, and certified components. Use rated lifting chains only.

Q: Does chain weight change my crane pick?

A: Yes. Add the chain’s mass (see table) and hardware weight to the load; the crane lifts both.

Q: G80 or G100—how do I choose?

A: Choose G100 when you need higher WLL or more headroom; choose G80 when you need cost-effective durability for everyday rigging.

Use the grade table, chain-weight figures, angle bands, and inspection rules in this guide to rig industrial lifting chains correctly—then contact TOPONE for a traceable quotation that matches your exact configuration and standards.