Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

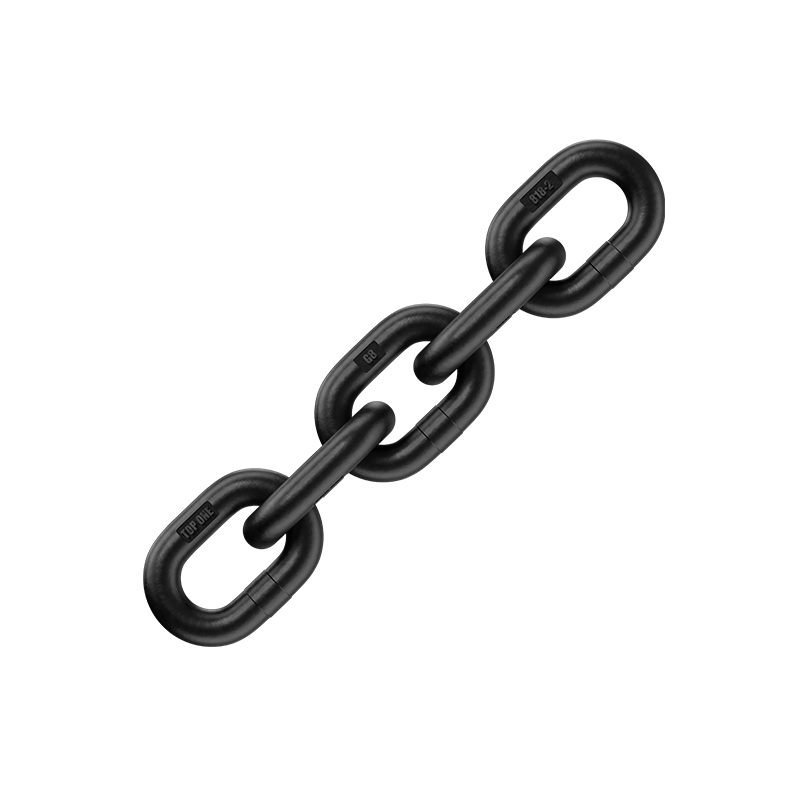

The GR80 chain, often referred to as a Grade 80 alloy chain, is globally recognized as the standard for overhead lifting. Its strength, durability, and compliance with international testing protocols make it the backbone of rigging systems across construction, mining, ports, and manufacturing. Understanding how GR80 chains align with regulations ensures both safety and efficiency in every lift.

A GR80 chain is manufactured from quenched and tempered alloy steel. Each link undergoes proof testing and inspection under recognized standards. The designation “Grade 80” signals that the chain is certified for overhead lifting applications, unlike commercial chains that lack structural guarantees.

Core identifiers of GR80 chains include:

Stamped grade mark (“8” or “80”) on each link

Traceable batch ID

Working Load Limit (WLL) certified by manufacturer

Compatibility with G80 components like hooks, master links, and connectors

GR80 chains are not just strong—they are regulated by specific international standards to guarantee consistent performance.

Standard | Coverage Area | Key Requirements |

EN 818-2 | Europe | Dimensions, mechanical properties, WLL, proof load testing |

NACM 2010 | USA | Manufacturing tolerances, tensile strength, link geometry |

ASTM A391/A906 | USA | Metallurgy, heat treatment, hardness parameters |

DIN 5687/5688 | Germany | Short link design, load calibration, testing methods |

These frameworks ensure that GR80 chains used in chain slings and rigging assemblies maintain global interoperability and safety compliance.

Construction: lifting beams, prefabricated concrete, structural steel

Mining: scraper conveyor chains, round link mining chains (DIN 22252)

Marine and Ports: mooring equipment, anchor handling, cargo rigging

Manufacturing: machine part handling, mold lifting, workshop hoists

Even a certified GR80 chain requires routine verification to stay safe. Operators follow strict inspection and retirement criteria:

Wear: retire when average diameter reduces ≥10%

Elongation: remove if pitch lengthens ≥3%

Hook compatibility: ensure throat clearance ≥10% of load point

Surface condition: reject for cracks, corrosion pits, weld spatter, or heat discoloration

Regular inspections align with ISO 7593 guidelines and national occupational safety rules.

While GR80 chains dominate standard lifting tasks, G100 chains are increasingly used where lighter weight and higher capacity are necessary. The table below highlights their main differences:

Feature | GR80 Chain | G100 Chain |

Strength Level | Standard alloy steel strength | ~20–25% higher WLL at same diameter |

Chain Diameter | Larger size needed for same load | Can reduce one diameter size |

Weight | Heavier per metre | Lighter per metre |

Cost | Lower purchase cost | Higher unit price |

Common Use | Construction, rental, general rigging | Production lines, restricted clearance, high-cycle lifting |

Temperature Range | –40 °C to 200 °C (normal) | –40 °C to 200 °C (normal) |

This comparison shows that GR80 chains remain the cost-effective, versatile choice, while G100 chains offer weight reduction and efficiency where conditions demand it.

https://www.lifting-chain.com/grade-80-series/

https://www.lifting-chain.com/grade-80-series/

The GR80 chain stands as the foundation of certified lifting practice because it merges strength with strict compliance. From construction to mining, its global standardization guarantees safety and reliability. Choosing GR80 chains from certified suppliers ensures every lift meets both performance and regulatory expectations. For proven quality, always source your GR80 chains from TOPONE CHAIN.