Our staff will contact you within 12 hours, You can also contact us through the following ways:

Contact US WhatsApp: +86 18263873187

- Email: [email protected]

- Tel: +86 18263873187

- Web: www.lifting-chain.com

A G80 chain sling is one of the most reliable rigging tools in lifting operations. Made from quenched and tempered alloy steel, it combines strength, flexibility, and resistance against demanding conditions. It is widely used in construction, ports, factories, mining, and logistics. Understanding its features, applications, and inspection guidelines helps ensure safety and efficiency across different industries.

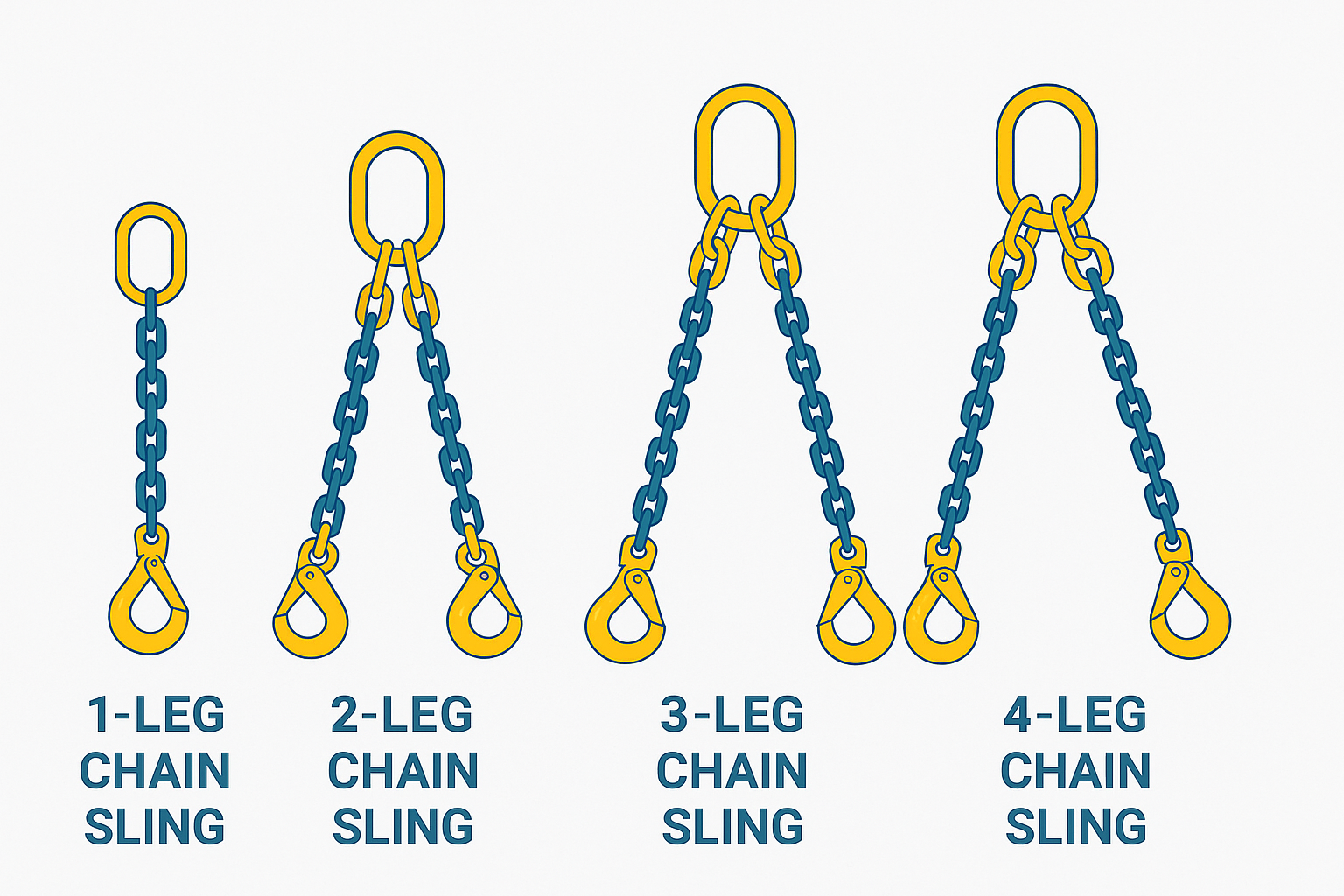

A G80 chain sling is a lifting assembly built with Grade 80 alloy steel chain, often combined with hooks, master links, or shortening clutches. It meets EN 818 and other international standards, making it suitable for overhead lifting. Its rated capacity depends on configuration, angle of use, and leg numbers (1-leg, 2-leg, 3-leg, or 4-leg).

Image: Close-up of a blue G80 chain sling with self-locking hooks attached to a steel beam

Different working conditions require different sling types.

1 Leg Chain Sling – for vertical lifting of balanced loads.

2 Leg Chain Sling – for lifting with better stability, often used for pallets and machinery.

3 Leg Chain Sling – allows even distribution on irregularly shaped loads.

4 Leg Chain Sling – provides maximum stability, used for heavy and uneven objects.

https://www.lifting-chain.com/grade-80-series/

The capacity of a G80 chain sling changes with the lifting angle. Operators must calculate correctly before use.

Table: G80 Chain Sling Capacity (Example, Ø 10 mm)

Configuration | Angle β (°) | WLL (t) |

1 Leg | 0° | 3.15 |

2 Leg | 0–45° | 5.6 |

2 Leg | 45–60° | 4.25 |

4 Leg | 0–45° | 11.2 |

4 Leg | 45–60° | 8.0 |

Values based on EN 818-4, may vary by manufacturer.

High strength: Designed for tough lifting tasks.

Versatility: Can be configured with various hooks and links.

Durability: Performs in –40°C to +200°C without loss of rated capacity.

Safety: Self-locking hooks prevent accidental release.

To maintain safe lifting solutions, users must inspect their chain sling regularly:

Wear: Remove if chain diameter reduces by 10% or more.

Elongation: Replace if pitch increases by 3%.

Cracks: Immediately retire cracked or deformed components.

Hook opening: Remove if throat opening enlarges by 10%.

Frequency: Conduct pre-use checks daily and thorough inspections annually.

Construction – lifting beams, prefabricated panels, concrete blocks.

Ports and Marine – container handling, anchor chain movement.

Factories – machinery lifting and assembly.

Mining – handling conveyor components and mining equipment.

The G80 chain sling provides strong, reliable, and versatile lifting performance when used correctly. With proper selection, inspection, and adherence to safety standards, it ensures efficient handling of loads across industries. Contact us today to explore certified lifting solutions.